Advanced Features Included as Standard

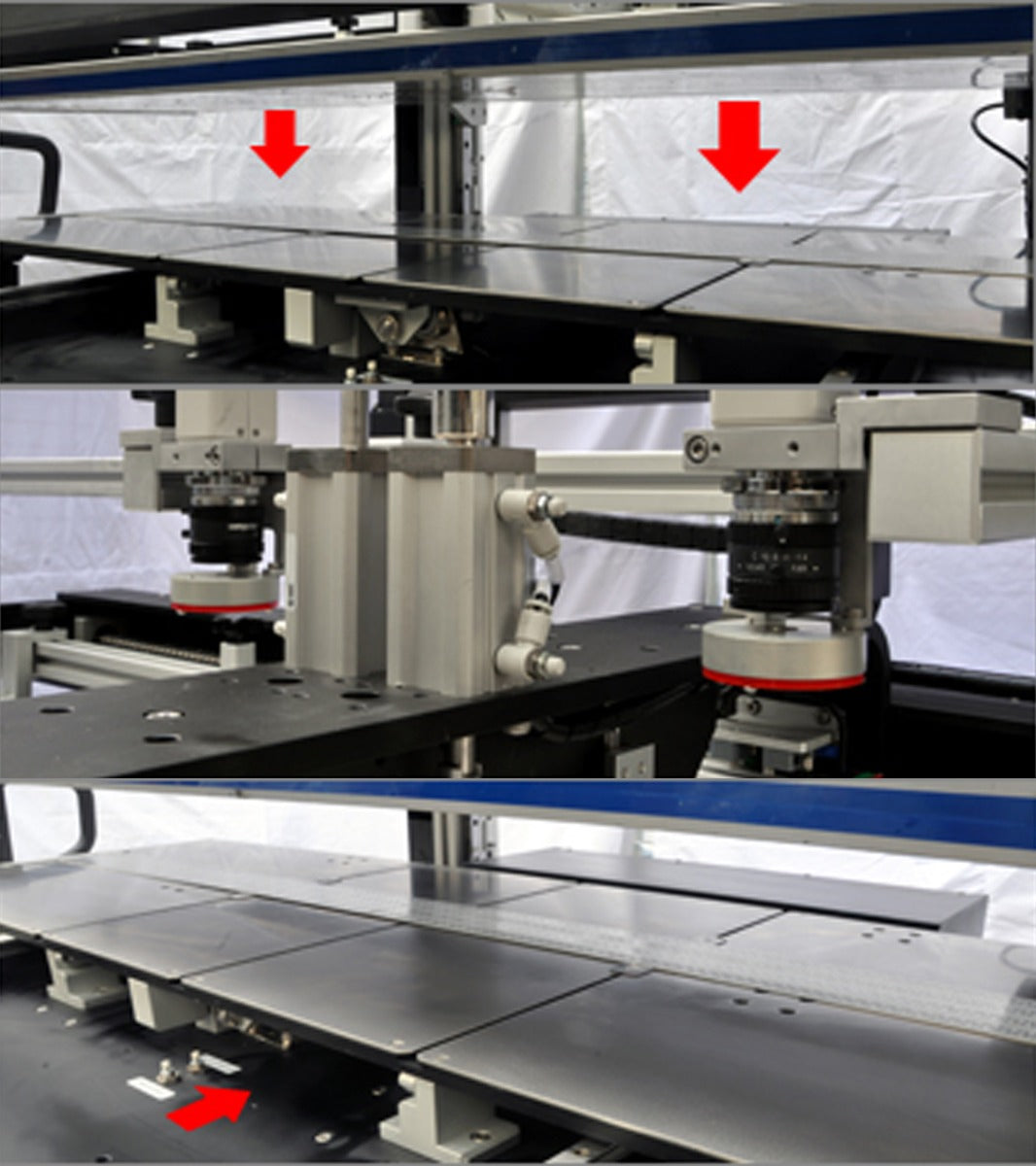

The MC600 has double-sided board printing capability and provides outstanding repeatability of ±0.01 mm. Vertical board/stencil separation ensures clean prints with excellent registration. Print speed control permits complex, fine-pitch circuit boards to be processed at slower speeds than simpler, less densely populated ones.

An optional dual-camera vision system shows X, Y, and theta alignments on an LCD screen. Once set, all adjustments remain locked-in during the entire run. Once the start button is activated, solder paste application and print stroking take place automatically. Squeegee movement and stencil separation speeds are fully programmable using the control panel.

Oversized Print Area—Custom Sizes Available

The MC600 features an oversized print area of 600 x 400 mm (23.6" X 15.75"). Custom print area sizes are also available.

Contact sales@manncorp.com to discuss options for your requirements.

Printing with the MC600 in Five Easy Steps

- Step 1:

- Place the PCB board on the slidable working table.

- Step 2:

- Press the IN button. The working table will move inside automatically.

- Step 3:

- Press the DOWN button and the stencil will automatically move downward.

- Step 4:

- Use the magnifying camera to adjust X, Y and theta alignments easily & precisely.

- Step 5:

- Press the START button to begin printing. The squeegee will then automatically begin to spread the solder paste.

| MC600 Specifications | |

|---|---|

| Stencil Frame Size | 350 x 350 mm to 736 x 470 mm |

| Max. Printing Area | 600 mm x 400 mm |

| Max. Board Size | 650 mm x 410 mm |

| X- and Y-Axes Range | ±13 mm |

| Theta Rotation | ± 3.5° |

| Underside Clearance | 25 mm |

| Z-Axis Range | 0-35 mm |

| Registration Repeatability | ± 0.01 mm |

| Power Requirements | 220VAC 50-60 Hz |

| Overall Dimensions (L x W x H): | 1064 mm x 1006 mm x 851mm |

| Machine Weight | 108 kg |