Spot-On Visual Alignment with HD Optics

The only SMT rework station in its price range to include true high-definition (HD) vision on par with the industry's most advanced rework systems, the RW1210 provides a crystal-clear superimposed image of the component leads and the PCB solder pads, even at 230X zoom. This is thanks to a combination of its 1.3 million pixel, split-vision CCD camera and high-brightness, independently controlled lighting for both the component and the PCB. Regardless of component pitch or size, your rework technician will have no trouble seeing when they've achieved perfect alignment on the system's 15" display.

No-Sweat ±0.02 mm Placement Accuracy

Precision rework with accurate—and quick—lead-to-pad alignment is made easy thanks to the RW1210's ultra-fine micrometer controls. The X- and Y-axis are controlled at the board holding fixture while the θ-axis (component rotation) is controlled at the pick-up head. Once placement has been activated, Z-axis height sensing guarantees gentle touch-down. All in all, the RW1210 rework station achieves mounting accuracy of ±0.02 mm, even when placing advanced SMDs such as µBGAs and ultra fine pitch QFPs with lead pitches as small as 0.3 mm (0.012").

Safe, Controllable Heating

The RW1210 SMD rework station has two hot air heaters, one top and one bottom, for fully controllable desoldering and resoldering that provides solid results without shifting even the smallest components.

For preheating, the bottom hot air heater is surrounded by a 2700W "Rapid IR" underheater. This 375 mm x 285 mm (14.76" x 11.22") IR preheater gently raises the temperature of the PC or LED substrate to prevent warpage and reduce stress on the components and solder joints adjacent to the rework site. The infrared heaters are fully enclosed in a glass-shielded compartment that quickly dissipates heat and prevents debris from falling into the elements, ensuring operator safety, reduced maintenance, and easy cleaning.

Quick Setup

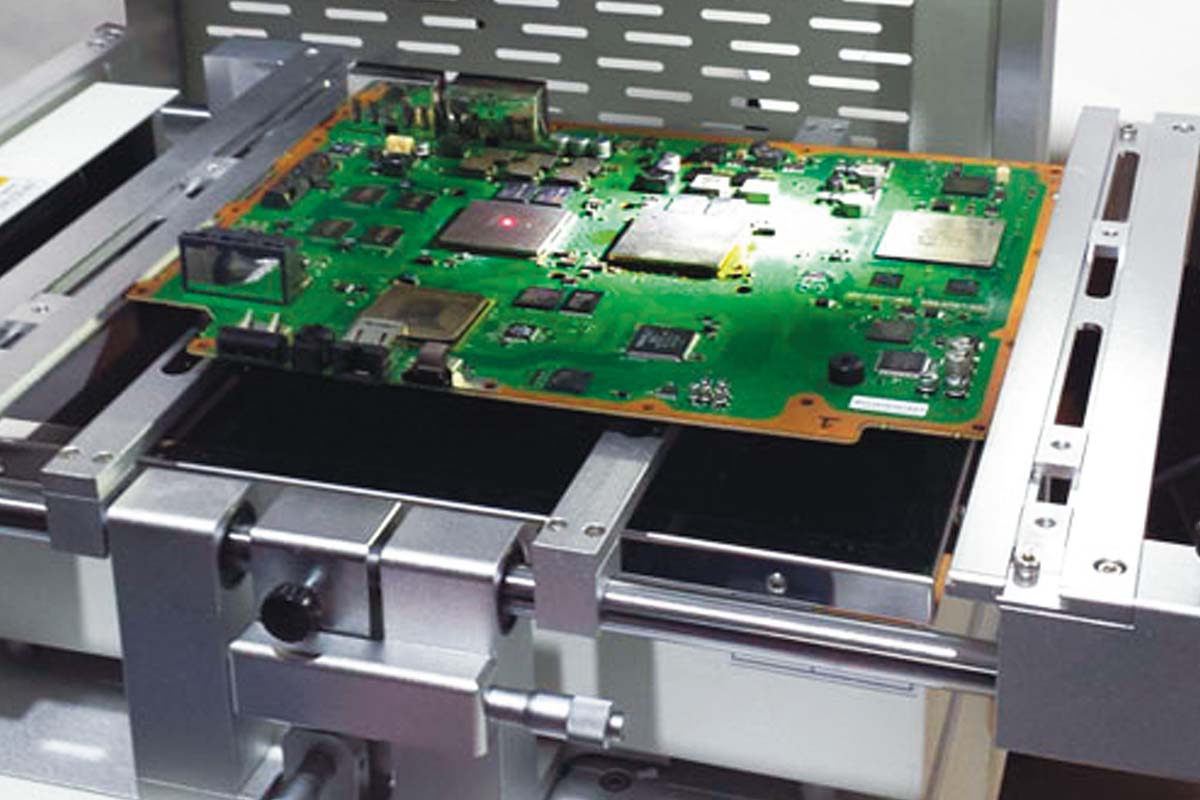

The rework station's universal board holding fixture adjusts quickly to accommodate virtually any board from 15 mm x 20 mm (0.6" x 0.79") to 412 mm x 370 mm (16.2" x 14.5"). When the underside of the PCB must be supported, adjustable pins and an additional set of rails are provided with the machine.

Once the board has been installed, high-precision edge rails and slide bearings provide smooth movement of the board. When the component to be reworked is located under the red laser dot that indicates alignment with the top and bottom heaters, the operator locks the fixture in place with convenient thumbscrews.

Designed for Ease of Use

The RW1210 rework station is controlled through a user-friendly touchscreen. Its ergonomically designed instrument panel includes joystick control for both camera zoom and, when the system is in manual mode, vertical control of the upper heater and placement head.

Dial adjustments control component and PCB lighting as well as air flow from the upper heater, precise control of which can prevent shifting of small chips during reflow.

The rework station's panel also includes a built-in K-type thermocouple input and a USB port for exporting solder temperature profiles to a flash drive.

For All Rework Tasks

Whether you're reworking complex PCBAs or simple LED assemblies, the RW1210 rework station for surface mount components handles your current projects and accommodates your evolving production needs well into the future.

| PCB SPECIFICATIONS | |

|---|---|

| PCB Size (Minimum) | 0.6" x 0.79" (15x20 mm) |

| PCB Size (Maximum) | 16.2" x 14.5" (412x370 mm) |

| COMPONENT SPECIFICATIONS | |

| Component Size | 2 mm x 2 mm to 60 mm x 60 mm |

| HEATING SYSTEM | |

| Area IR Under-Heater | Max. Heat Area - 375 mm x 285 mm (2700 W) |

| Component Heater (Top Side) | Hot Air (1450 W) |

| Component Heater (Bott. Side) | Hot Air (1200 W) |

| Temperature Control | K-Type Thermocouple; Closed Loop |

| UTILITY SPECIFICATIONS/FACILITY REQUIREMENTS | |

| Main Power Source | 220 V / 50/60 Hz |

| Total Power Consumption | 5.65 KW Max. |

| Machine Dimensions | 685 mm L x 633 mm W x 850 mm H (not including LCD display) (27" x 25" x 33.4") |

| Net Weight | Approx. 168 lbs (76 kg) |