SMD Component Variety and Placement Accuracy

The MC392 comes standard with the ability to place parts as small as 01005s with a placement accuracy of 30 µm, 3 Sigma. At the other end of the spectrum, MC392 can place SMDs as large as 100 x 150mm.

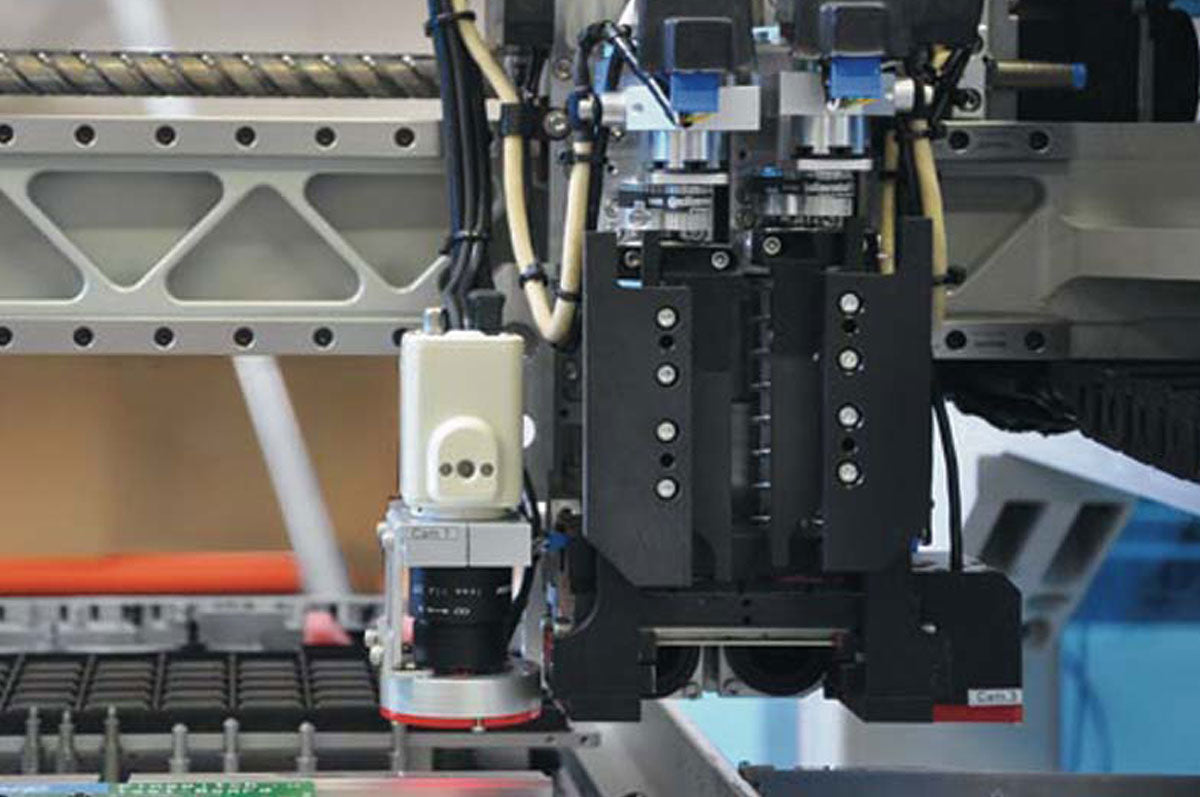

Alignment is accomplished via a dual-vision combination of Cognex® (head-mounted) on-the-fly cameras and a stationary, bottom (upward-looking) camera for accurate and efficient alignment of just about any components, including:

- BGAs

- µBGAs

- CSPs

- Micro Lead Frames (MLFs)

- Fine-pitch QFPs down to 0.3 mm/0.012" lead pitch

- Odd form components

- And more

MC392's full-vision alignment, which matches component leads, balls, or bumps directly with the pads, completely eliminates placement inaccuracies caused by systems that locate and align to only the component body.

Large Feeder Capacity for Faster Job Changeovers

The standard machine is configured as batch/stand-alone; two 48-port feeder racks can be installed on the front and rear of the machine, and two 32-port feeder racks on the sides, for a total of 160 feeder ports. Usable with Smart Tape Feeders and stick/tube feeders.

Alternatively, a 3-stage inline conveyor can be installed for more automation, and then two 48-port feeder racks can be mounted on the front and rear of the machine for a total of 96 feeder ports.

In either case, waffle trays, bulk loose parts trays, and cut strip tape holders can be placed in the generous 13.8" x 23.6" to 26" (350 mm x 600 to 660 mm) working area.

Designed for Timesaving and Performance

The MC392 has been designed to save time and perform at a high level by including the following features:

- Placement software analyzes and optimizes feeder locations to minimize head travel and tool changeovers and maximize efficiency and throughput.

- Plug-and-Play Smart Tape and Stick Feeders allow you to set up jobs easily and keep changeover times low.

- Ultra-smooth electronic tape feeders index parts to the same place every time.

- Universal stick feeders adjust to virtually any SMD length, width, or tube packaging dimensions.

- Cut tape strip holders allow component to be purchased in quantities less than full reels.

The use of a bar code scanner together with the offline feeder programming software can save time and prevent incorrect data input from operator error.

Reliability & Repeatability for Your Customers

Whether you're manufacturing boards for other companies or producing your own end-product, your customers rely on your manufacturing line's capabilities. MC392, with its high-quality build and internal components, is dependable. A highly precise ball-screw drive is combined with high-performance servo motors and non-contact rotary encoders, housed in a heavy-duty, welded steel frame to provide high accuracy, repeatability, and stability even at top speeds.

All parts will be covered by our standard 1-year warranty. Find out more about Manncorp Warranties. Additionally, the MC392 includes a network adapter and remote service support software, allowing Manncorp techs to troubleshoot the machine remotely for the fastest problem resolution.

Easy to Use, Field-Tested Software

The MC392 uses the same robust, Windows®-based software as all other MC series machines. Customer feedback over the past ten years has created a very easy to use, stable and reliable system.

- Program via CAD import and conversion, teaching, or direct entry.

- Component data links to Smart Feeder software for easy setup and inventory control.

- Virtual PCB Simulator displays a virtual assembly based on programming data.

- Fiducial mark search routines identify and correct for PCB offset or misalignment.

- Optimization tools analyze data and mix to provide feeder arrangements that minimize head travel and tool changes.

- Remote diagnostic software allows for fast troubleshooting by Manncorp techs.

| Placement Specifications | |

|---|---|

| Number of Placement Heads | 2 |

| Placement Rate (IPC-9850)* | 5,500 CPH |

| Placement Rate (Max.) | 6,400 CPH |

| Placement Accuracy | 30 µm, 3 Sigma |

| Minimum Component Size | 01005 |

| Maximum Component Size | 100 mm x 150 mm (3.94" x 5.9") |

| Maximum Component Lead Pitch | 0.3 mm (0.012") |

| BGA/CSP Placement Capability | Yes - Standard |

| Alignment Method | Dual-Vision Alignment System |

| Pick Up Specifications | |

| Nozzle Changer | Included |

| Number of Nozzles | 14 |

| Accepts Additional Nozzles | Yes |

| Integral Vacuum | Yes |

| PCB Specifications | |

| PCB Loading Method | Manual (Batch), 3-Stage Inline Conveyor or 2-Stage Long-Board Conveyor |

| Maximum Placement Area | 350 mm x 600 mm (13.8" x 23.6") w/o conveyor (stand-alone) 315 mm x 650 mm (12.4" x 25.6") with inline conveyor 330 x 1200 mm (13" x 47.3") with 2-stage long-board configuration |

| Fiducial Recognition / Coordinate Correction | Yes |

| Bad Mark Detection | Yes |

| Feeder Capacity | |

| Maximum Number of Feeder Ports | 160 |

| Maximum Number of Waffle Trays | 1 standard, more optional depending on machine layout |

| Programming | |

| Operating System | Windows® Based |

| PC, Keyboard, Mouse | Yes |

| Monitor | Flat LCD |

| Teaching Camera | Yes |

| Numeric Data Entry | Yes |

| CAD Download | Yes |

| Step and Repeat for Matrix Boards | Yes |

| Bar Code Reader for Feeders & Packaging | Yes |

| MIS and Optimization Functions | Yes |

| Off-Line Programming | Yes |

| Dispenser Specifications | |

| Dispensing Head | Optional |

| Dispense Method | Time/Pressure |

| Dot Size/Placement Speed |

Down to 0.5 mm |

| Mechanical Specifications | |

| X-Y Axis Drive Mechanism | Ball Screw |

| X-Y Axis Drive Motors | AC Servo |

| X-Y Axis Encoding | Rotary |

| X-Y Axis Resolution | 0.005 mm (0.0002") |

| X-Y Axis Repeatability | ±0.01 (10 µm) |

| Z Axis Drive Motor | DC Servo |

| Z Axis Encoding | Rotary |

| Z Axis Resolution | 0.02 mm (0.0008") |

| θ Axis Drive Motor | DC Servo |

| θ Axis Encoding | Rotary |

| θ Axis Resolution | 0.045° |

| θ Axis Range of Motion | 360° |

| Physical Specifications | |

| Overall Dimensions (Approx. L x W x H) | 1190 mm L x 1140 mm W x 1346 mm H (47" x 45" x 53") |

| Approximate Net Weight | 550 Kg (1213 lbs.) |

| Facility Requirements | |

| Standard Voltage | 200-230 VAC, 50/60 Hz, 7A |

| Air Pressure | 80 psi, 8 CFM |

| Service and Support | |

| Remote Diagnostics | Ethernet |

| Warranty (Major Components) | 1 Year |

Because feeder management and control software is included as part of the MC series pick & place software, smart feeding is standard on every MC series pick & place machine. A wide range of affordable, efficient and reliable smart tape and stick feeders are available, as well as waffle tray and cut tape strip holders.

- High-precision design

- Built-in memory modules and COM ports

- Ultra-smooth electronic actuation and tape advance

- Smart data linking optimizes setups, speeds job changes

- Prevent feeders from being loaded in the wrong ports

- Bar codes can be used for quick data entry and verification

Innovative Feeder with a Built-In Display

Information is stored directly, and constantly updated, within this new feeder. The OLED screen allows operators to review component quantities on reels, feeder slot locations, part numbers, part values, and more - all while the machine is in-use or offline. Being able to view this vital information on the feeder itself adds an extra level of insurance that the correct parts will be placed accurately from the onset, fixing problems before reaching the inspection stage.

- Component reel information is now stored/updated in the feeder.

- OLED displays allow for easy monitoring of the component consumption status.

- The feeder has an internal battery, so data will always be available in both online (connected to machine) and offline (standalone) modes.

- Vision library names are displayed (for example 0201, SOIC16, QFP44, etc.) and the feeder stores the lot & date codes of components.

Slim Design Maximizes Capacity

Manncorp MC series Smart tape feeders set a new standard for accurate, dependable and economical SMD presentation. The slim-profile design of these smart feeders maximizes the number of feeders that can be mounted in the space available on the pick and place machine.

Unique IDs Access Relevant Feeder Data When Feeder Is Plugged In

Each smart tape feeder has a DB-9 interface connector on its front end. The DB-9 plugs into any MC series smart feeder base to allow communication between the MC series control software and the memory module that's built into each feeder. The memory module stores a unique feeder ID number that, as soon as the feeder is plugged into a base, instantly links it with its relevant data: assigned feeder position (port), feeder size and type, component value, lot code, date code, starting quantity, index increment, and package type.

Automatic Index Adjustment Prevents Pick-Up Errors

MC series pick & place machines can use vision to calculate the offset of the component tape from the taught pickup position and index the tape feeder forward or backward accordingly. This feature is especially useful when reloading a feeder with a new reel where the alignment of the tape pocket position is slightly off from the position of the previous reel. If pickup errors associated with loose tolerances between components and tape pockets are a problem, this feature can be set to check and index on every pickup for the feeders with the problem tape reels.

Full Range of Feeder Sizes

Smart tape feeders are available in 8 mm to 72 mm widths with programmable tape index settings from 2 mm to 36 mm. Variable tape index settings, from 16 mm to 26 mm, can also be stored in the smart feeder memory modules. This is particularly useful for 32 mm through 72 mm tape widths when extra component length requires more than the standard 4 mm, 8 mm or 12 mm tape index. Storing these setting in the memory module ensures that the settings will be used for that feeder regardless of where it is loaded—even if it is loaded on a different machine.

Smart Tape Feeder Carts for Storage and Off-Line Kitting

Transport, store, and protect your valuable Smart Tape Feeders with the sturdy, dual-tiered Smart Tape Feeder Storage Carts. The model FR-ST64 (shown) holds as many as 64 individual 8 mm Smart Tape Feeders. This handy accessory can be wheeled easily from the kitting area to the production floor and organizes feeder handling for quick and efficient setup and changeover. The heavy-duty tubular construction holds each feeder securely and shields them from impact as they move around the assembly floor.

Tape Feeder Specifications

These tape feeders work with all Manncorp MC series pick and place machines.

| Model # | Tape Size | Minimum Index Step | Maximum Tape Thickness | Feeder Base Port Positions Occupied | Feeder Slot Pitch |

| KFTA2-8MM HS | 8 mm | 2 mm | 3.3 mm | 1 | 13.3 mm |

| KFTA2-8MM | 8 mm | 4 mm | 3.3 mm | 1 | 13.3 mm |

| KFTA2-12MM | 12 mm | 4 mm | 7.0 mm | 2 | 13.3 mm |

| KFTA2-16MM | 16 mm | 4 mm | 12.0 mm | 2 | 13.3 mm |

| KFTA2-24MM | 24 mm | 4 mm | 12.0 mm | 3 | 13.3 mm |

| KFTA2-32MM | 32 mm | 4 mm | 12.0 mm | 3 | 13.3 mm |

| KFTA2-44MM | 44 mm | 4 mm | 12.0 mm | 4 | 13.3 mm |

| KFTA2-56MM | 56 mm | 4 mm | 12.0 mm | 5 | 13.3 mm |

| KFTA2-72MM | 72 mm | 4 mm | 12.0 mm | 6 | 13.3 mm |

| KFTA3D-8MM SW | 8 mm | 2 mm | 3.3 mm | 1 | 15 mm |

| KFTA3D-8MM | 8 mm | 2 mm | 3.3 mm | 1 | 15 mm |

| KFTA3D-12MM | 12 mm | 4 mm | 7.0 mm | 1 | 15 mm |

| KFTA3D-16MM | 16 mm | 4 mm | 12.0 mm | 2 | 15 mm |

| KFTA3D-24MM | 24 mm | 4 mm | 12.0 mm | 3 | 15 mm |

| KFTA3D-32MM | 32 mm | 4 mm | 12.0 mm | 3 | 15 mm |

| KFTA3D-44MM | 44 mm | 4 mm | 12.0 mm | 4 | 15 mm |

| KFTA3D-56MM | 56 mm | 4 mm | 12.0 mm | 5 | 15 mm |

| KFTA3D-72MM | 72 mm | 4 mm | 12.0 mm | 6 | 15 mm |

- Universal design adjust to virtually any SMD length, width, or tube packaging dimensions

- Available with 5, 10 or 20 lanes

- Mount directly on MC series smart feeder bases, alongside smart tape feeders

- Memory modules link feeder lanes to specific component data

Universal Stick Feeders for Flexibility

Manncorp smart stick feeders can be positioned directly adjacent to Manncorp smart tape feeders and, like the tape feeders, are able to communicate with the MC series software via DB-9 interface connectors that plug into the smart feeder base. The memory modules store unique ID numbers that link the individual lanes in the feeder hardware with relevant feeder data, including assigned feeder position, component data, belt indexing increments, and on/off time control settings for the vibratory/gravity feed portion of the feeder.

Tape Feeder Specifications

These tape feeders work with all Manncorp MC series pick and place machines.

| MODEL # | MAX. NUMBER OF STICKS/TUBES | VIBRATORY/GRAVITY FEED ZONES | FEEDER BASE PORT POSITIONS OCCUPIED |

| KFTB-2 | 10 | 2 | 9 |

| KFTB-4 | 20 | 4 | 17 |

- Included as standard with all MC series pick and place machines

- Position scanning for fast changeover

- Automatic component quantity tracking

- Quick-change feeder locations

- Feeder position verification

- Cut out manual data entry

Automatic Component Quantity Tracking

The software also tracks the number of components used, updating each feeder's memory module at the end of the production run with the quantity remaining on the reel (based on the number of pickups). This value, like the feeder ID, is retained with the feeder even after the feeder has been removed from the feeder base. When that feeder is loaded for new—or even a different—production run, the component quantity will be read from the smart feeder back into the assembly program so that an accurate component count can continue.

Feeder Position Verification

When using optimized feeder positions (a feature included in the MC series software), smart feeder IDs can be verified against feeder position data to ensure that the correct feeders are in the correct connector ports.

Position Scanning for Fast Changeover

When optimized feeder positions are not used, the system can automatically scan the loaded feeders for their IDs and inform the assembly program of each pick-up's feeder location.

Quick-Change Feeder Locations

If the operator, for whatever reason, has to position the smart feeders in a different arrangement on the machine or doesn't want to reposition smart feeders that are used in consecutive production runs, the Change Feeder Location Function can be used to import the new feeder ID data into the pick and place file.

Cut Out Manual Data Entry

An optional bar code reader can make quick work of reading and entering component data, including value, lot code, date code and starting quantity, directly from the reel or other packaging.

- MC series pick and place machines feature large, open work areas that accept a variety of holders for trays and cut tape strips

TS-1 Tray Holder

TS-1 tray holder occupies approximately 13" x 5.5" (330 mm x 140 mm) of work area and is designed to hold a standard 12.4" x 5.35" (316 mm x 136 mm) JEDEC Matrix Tray or up to two cut strip tape holders. The TS-1 provides adjustability for a wide variety of smaller matrix tray and waffle pack combinations and can easily be modified for custom tray configurations.

CST Cut Strip Tape Holders for Short Lengths of Taped Components

CST Cut Strip Tape Holders are a handy accessory for presenting components that are supplied in short lengths of tape due to their low quantity of usage or to prevent the waste of components in sections of tape that are too short to be loaded into tape feeders. This photo shows standard holders for 8 mm, 12 mm, 16 mm and 24 mm tapes. Other sizes are available upon special request.

Stand-Alone Configuration (Standard)

| Max. Placement Area | 560 mm x 350 mm |

| Maximum Number of Feeder Ports | 160 |

| Max. Feeder Ports (Front) | 48 |

| Max. Feeder Ports (Rear) | 48 |

| Max. Feeder Ports (Right) | 32 |

| Max. Feeder Ports (Left) | 32 |

In/Out Conveyor Configuration (Option)

| Max. Placement Area | 315 mm x 650 mm (12.4" x 25.6") |

| Maximum Number of Feeder Ports | 96 |

| Max. Feeder Ports (Front) | 48 |

| Max. Feeder Ports (Rear) | 48 |

| Max. Feeder Ports (Right) | 0 |

| Max. Feeder Ports (Left) | 0 |

Inline Conveyor Configuration (Option)

| Max. Placement Area | 330 mm x 1200 mm (13" x 47.25") Length is done in 2 stages, 600 mm/stage |

| Maximum Number of Feeder Ports | 96 |

| Max. Feeder Ports (Front) | 48 |

| Max. Feeder Ports (Rear) | 48 |

| Max. Feeder Ports (Right) | 0 |

| Max. Feeder Ports (Left) | 0 |